Jack Schmidling Productions, Inc.

18016 Church Road ~ Marengo IL 60152

Phone:815 923 0031 ~ Fax:815 923 0032 ~ Email:jack@schmidling.com

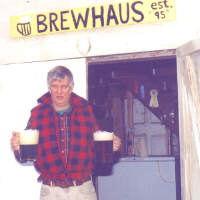

As is true of all the world's great breweries, the World's Greatest must be judged by the quality of the beer not by external (or internal) appearances.

Our brewery is installed in a small barn that is shared with chickens, racoons, bats and a host of other guests. We have running water and propane but no heat so the brewing season runs for March to Octoberfest.

The lower level contains (from left to right) the 16 gal brew

kettle, 10 gal mash tun and the converted chest freezer that is

maintained at 40 degrees F. Note also the many ribbons

and trophies casually hanging about, attesting to the

universally acknowledged, superior quality of the "World's

Greatest Beer".

We brew two styles of beer, more or less on an alternate batch basis. Our most prized is our clone of the world re-knowned Pilsner Urquel. It is made from Belgian malt, yeast cloned from the brewery in Pilsen, Czechoslovakia and hops grown right behind our brewery. Most experts can not tell the difference between ours and the original but true connoisseurs prefer ours.

The other beer is a dark beer in the traditional style of Munich. It uses the same hops and yeast but the malt is darker Munich malt. Experts, of course, consider it the World's Greatest Dark beer.

The loft contains the sparge water tank and a

propane heater. Marilyn is seen here filling it with the world

famous Marengo Spring Water. The hot water is gravity feed to a

valve over the mash tun below.

The lagering room is where lager beer lagers or rests until it is ready to serve. Our scaled down version is actually a chest freezer with a special temperature controller that makes it think it is a refirgerator.

From left to right we have the most recent beer fermenting, the

previous batch aging and "conditioning" in a 10 gal

pressurized keg and finally, the one we are currently drinking

from. The cycle time is about 60 days from brew day to serving.

The brew cycle begins when the serving keg splutters and gasps the last bit of foam. The empty keg is removed from the cooler and thoroughly cleaned and sanitized with bleach and rinsed until the last trace of bleach is gone. It is then returned to the cooler ready to receive the beer from the fermenter.

A pump mounted under the table is attached to the fermenter spigot and the output hose is attached to the clean keg and the beer is transfered to the keg.

What is left in the "empty" fermenter, is about half an inch of yeast sludge. About half of this will betransfered to a small sterilized kettle so the fermenter can be cleaned and sanitized. The yeast will be used to start the next batch.

The mash tun (a 10 gal kettle) is filled with 6 gallons of water and covered to await the actual brew day on the following day. The sparge water tank is also filled with about 15 gals of water for the next day.

The brew day actually starts with the

lighting of the burner under the mash tun. While this is heating

up, 15 lbs of malt are weighed out and milled in (what else?) a MALTMILL. When the water reaches about

160F, the burner is turned as low as it will go, the MIXMASHER is turned on and the malt is slowly

added to the water.

When all the malt is in, the temperature is checked and the flame

either turned on or off to maintain a temperature of about 155

degrees. The burner under the sparge water tank is turned on and

should bring it to near boiling by the time the mash is complete.

After about 30 mins, the iodine test is performed to determine the degree of starch conversion. If judged to be complete, the flame is turned on or left on and the temp allowed to rise to about 170F over about another 30 min. The heat is turned off and the lid placed on the mash tun.

After the mash has settled, it is drained and flushed in a process called sparging. Inside the mash tun is a device called an EASYMASHER which is simply a tubular screen connected to the spigot on the outside. The spigot is connected to a length of copper tubing that allows the sweet wort to flow into the brew kettle. Hot water from the sparging tank in the loft flows into the mash tun to replenish the wort that flows out. The curved copper tube above the mash tun is perforated with small holes to provide a sort of sprinkler head to distrubute the water.

About a quart of turbid sweet wort is collected and returned to the mash tun prior to connecting the outflow tube. The input water and out flow are regulated to maintain about an inch of water on top of the grain bed.

As soon as the filling of the kettle begins, roughly one half

of the total hops is added to the kettle. The wort flow is

adjusted to maximum and when about the 5 gallons are in the

kettle, the burner is turned on to start the boil. When the 10

gallon mark is reached, the sparge water is turned off and the

outflow reduced to slowly drain the mash tun of the remaining

sweet wort to bring the total wort level to about 12 gallons.

When the wort begins to boil, about half the remaining hops is

added and this is repeated every thirty minutes untill the wort

is reduced to 10 gallons. This takes about 90 minutes. When the

boil is complete, the burner is turned off and the wort allowed

to air cool for about thirty minutes at which time the lid is put

on and we are done for the day.

During the boil, we have cleaned out the mash tun and the spent grain is given to the chickens or saved and dried for bread or both.

On the next morning, about a quart of water is brought to a boil in the fermenter and allowed to boil for a few minutes with the lid on to sterelize. When cool, it is placed in the cooler and the yeast we saved is poured into it.

The now cool wort is pumped from the brew kettle into the fermenter and the lid is placed on it to ferment till the next cycle begins.

Our brew season ends with our OCTOBERFEST/STAR PARTY on the first Saturday in October. When the homebrew is gone, we are really "out of beer".

[ BEER PAGE]