| ORDERING INFO | MALTMILL PAGE | BEER PAGE | HOME PAGE |

![[MALTMILL photo]](bb.jpg)

| ORDERING INFO | MALTMILL PAGE | BEER PAGE | HOME PAGE |

![[MALTMILL photo]](bb.jpg)

The basic BBP consists of a set of Pre-adjusted rollers installed in the bearing plates and the front and rear containment panels.

There are no compromises or changes from the standard MALTMILL which will process a pound of grain in less than 15 seconds and enough for a five gallon batch in under five minutes with the hand crank. When motorized, it can crush at a rate in excess of 1000 lbs per hour. At 400 RPM, it takes 3.3 seconds to crush one pound.

A large funnel or bucket with a hole in the bottom can be placed on top for a hopper and another bucket under the mill to collect the grist.

It also features the Gear Drive Option and optional hand crank on the Adjustable (BBA) version.

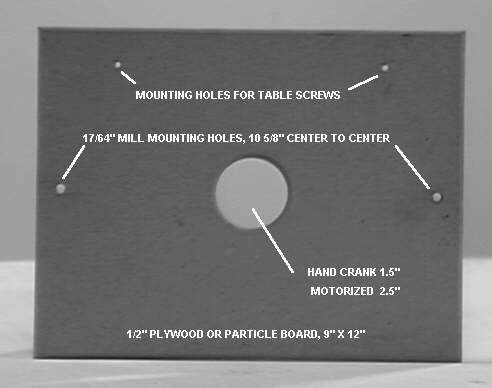

The hopper deck seems to be the simplest method of mounting the mill to a table. It can be purchased from us or made with simple tools and the only critical dimension is the spacing between the mill mounting screws.

The traditional way of mounting the mill is on top of the table with a slot under it for the grain to fall through to a bucket below.

This drawing shows the layout of the slot and mounting holes for the table top mounting.