| ASTRONOMY | BEER | CHEESE | GEMS | PRESERVED FOOD | VIDEO | HOME |

NOTE: This page is maintained for informational purposes only. We no longer offer this product for sale.

Making anything more exotic than tumbled stones has been (up until now) not for the faint of heart or light of pocket. Even the simplest faceted stone requires the investment of several thousand dollars in a commercial faceting machine.

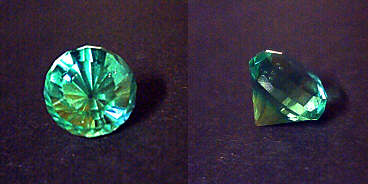

Most folks are turned off by this predicament and leave the craft to the more affluent. I found myself in this situation and decided to see what I could do about it. All of the stones in this picture were cut with the EasyGem described here.

The EasyGem will do anything that a more expensive machine will do but like an artist's paint brush, you get what you put into it.

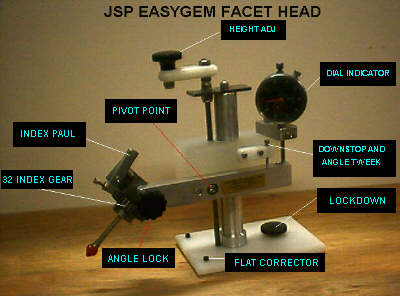

It consists of a 200 RPM diamond charged aluminum lap and a gear indexed faceting head.

The lap is charged on both sides for a coarse and medium cut. Un-grinding and polishing are done on paper laps that are charged with diamond pastes also supplied with the machine.

For the more advanced faceter, we also offer a version of the highly acclaimed BATT® lap as an option for polishing.

After setting the angle with the protractor supplied and adjusting the height of the stone to meet the lap, it is ground until the arm hits the stop and the dial indicator reads zero. At this point the stone is rotated to the next position on the index gear and the process repeated.

After "roughing in" all the facets, the process is repeated with progressively finer diamond charged paper or metal laps.

The rough stone, (in this case a red marble) is epoxied to a brass rod known as a dop. The dop is inserted into the index gear and locked with a setscrew. The end of the dop is inserted into the index head at the position prescribed for the particular design. We provide a number of easy gem designs and specific instructions for making them but literally thousands of others are available on the web. You can also download software to do your own designing.

After grinding a facet, the spring loaded "paul" is depressed and the gear rotated to the next position and the next facet is ground.

A faceted stone has two sides, the "crown" on top and the "pavilion" on the bottom. The pavilion is usually done first and as the crown side was attached to the dop, it can not be faceted until the dop is removed.

Before the crown dop can be removed, a pavilion dop must be attached perfectly aligned with the crown dop so that when this is removed, the stone will maintain the same orientation in the machine.

Attaching the new dop is known as "transfer" and is done using a transfer fixture. This is another expensive accessory that we have simplified for the less than affluent hobbyist. Our fixture consists of a PVC base with a "V" grove milled across it's length, a hole in the middle to clear the stone and two clamps to firmly hold the dops in precise alignment while the epoxy is setting.

After the epoxy has set, the crown dop is heated over a flame until it falls off leaving the stone attached to the pavilion.

I have been so fascinated by the beautiful gems that can be made with marbles, I have hardly tried anything else but for a few more examples of gems made with this machine, see GEMS

At this point in time, the pricing is as follows:

Faceting head...........$300

BATT®jr lap........$40 ea*

The Lappping Machine includes:

The Faceting Head includes:

BATT®jr is a 4" version cast for us from the proprietary alloy by the original manufacturer.